|

QINGDAO JBD MACHINERY CO., LTD

|

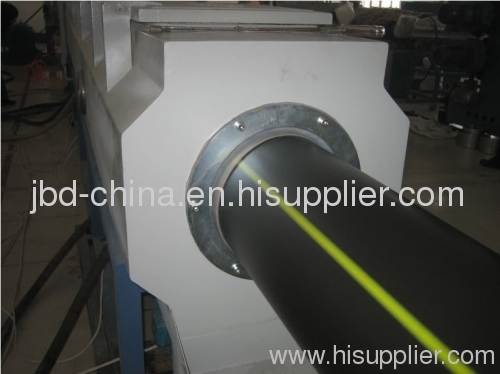

PE water supply and gas pipe production line

| Price: | 80000.0~240000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Pipe material:PP/PE

2.Main motor power:200kw

3.Output:500kg/h

4.Total power:450kw

5.Cutting power:3kw

PE Pipe used in many fields, such as single layer pipe,multi-layer composite pipe, agriculture irrigation pipe and cable protection pipe.

J.B.D PE water supply and sewage pipe production line has its own structures,the key points are as follows: The extruder adopts PE high-efficiency screw, notched feeding cylinder and is equipped with strong water jacket cooler, which greatly improves its transmission capacity and guarantees high-efficiency extrusion.

The basket composite die head adapted for PE processing not only guarantees extrusion stability at high speed, but also realizes minimum stress and highest pipe quality in low temperature.

The high-efficiency double-cavity vacuum sizing technology and spray cooling tank improves the rate of finished product and meets the need of high-speed production.

Adopt multi-caterpillar to drive all pedrails through central motor to get synchronous height and guarantees pipe's roundness.

The high-speed, precise designed cutting machine is low in noise. And it is also equipped with strong scrap attracting device to reduce the work of maintenance to the lowest degree.

Equipment lists of PE water supply and gas pipe production line

J.B.D PE water supply and sewage pipe production line has its own structures,the key points are as follows: The extruder adopts PE high-efficiency screw, notched feeding cylinder and is equipped with strong water jacket cooler, which greatly improves its transmission capacity and guarantees high-efficiency extrusion.

The basket composite die head adapted for PE processing not only guarantees extrusion stability at high speed, but also realizes minimum stress and highest pipe quality in low temperature.

The high-efficiency double-cavity vacuum sizing technology and spray cooling tank improves the rate of finished product and meets the need of high-speed production.

Adopt multi-caterpillar to drive all pedrails through central motor to get synchronous height and guarantees pipe's roundness.

The high-speed, precise designed cutting machine is low in noise. And it is also equipped with strong scrap attracting device to reduce the work of maintenance to the lowest degree.

Equipment lists of PE water supply and gas pipe production line

Equipment lists | Model | QTY | Remark |

Automatic feeding machine | ZJ600 | 1set | |

Single screw extruder | SJ-150/33 | 1 set | |

Single screw extruder | SJ-30/25 | 1 set | Marking line |

Mold | 400-950 | 1 set | |

Vacuum calibrating tank | ZK-950 | 1 set | |

Spraying tank | PL-950 | 2 set | |

Six claws haul off machine | QY-950 | 1 set | |

Planetary cutting machine | XQG-950 | 1 set | |

Stacker | FL-950 | 1 set |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Pe Pipe Production Line

Water Gas Supply Pipe

Pe Double Wall Corrugated Pipe Production Line

Pe Pipe Extrusion Line

Pipe Production Line

PVC Pipe Production Line

More>>