|

QINGDAO JBD MACHINERY CO., LTD

|

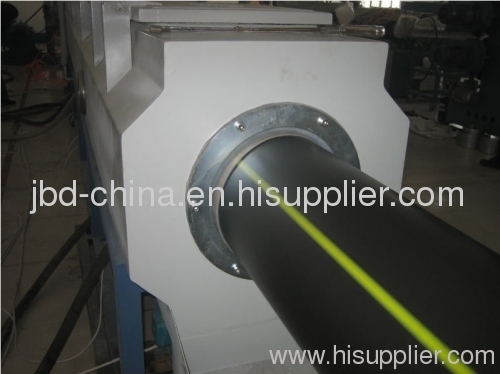

HDPE water supply and drainage pipe making machine

| Price: | 80000.0~100000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Extruder:SJ120/33

2.Length of production line:46m

3.Output:350kg/h

4.L/D:33:1

5.Total power:280kw

HDPEwater supply and drainage pipe making machine contains:

1. extruder,(main extruder and label extruder)

2. moulds(as per requests of users)

3. vacuum forming tank

4. spray cooling tank

5. multi-claws haul off

6. cutter

7. stacker

HDPEwater supply and drainage pipe processing machine Introduction:

HDPEwater supply and drainage pipe processing machine Introduction:

This extruder equipped with barrier unit and mixing structure, the barrel is new style grooves.

All of these offer good plastification and mixing effect.

1.Special design of basket die head of for HDPE large diameter pipe with thick wall offer lower

temperature, good mixing, lower pressure of cavity, and stable production.

2.Special design for sizing and cooling system by using film and water to cool HDPE material,

2.Special design for sizing and cooling system by using film and water to cool HDPE material,

which can fit for the requirement of HDPE(PP, ABS). And the design can ensure the stability of diameter and roundness when producing

the pipe with thick wall.

3.Special design vacuum sizing tank can ensure the stability of size and roundness, Speed

3.Special design vacuum sizing tank can ensure the stability of size and roundness, Speed

controllers are used in extruder, haul-off to offer stability and precision.

Technique details of HDPEwater supply and drainage pipe making equipment

Pipe range(mm) | Model | Capacity(kg/h) | Hauling speed(max.mm/min) | Totalpower(kw) | Length (m) |

20-110 | SJ65/33 | 100 | 8 | 130 | 27 |

75-160 | SJ90/33 | 200 | 6 | 150 | 30 |

90-250 | SJ90/33 | 200 | 5 | 200 | 32 |

160-400 | SJ120/33 | 350 | 4 | 280 | 46 |

200-500 | SJ120/33 | 350 | 3 | 380 | 52 |

315-630 | SJ150/33 | 450 | 1 | 400 | 56 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Hdpe Water Pipe Fittings

Hdpe Drainage

Water Supply Pipe

Water Gas Supply Pipe

Pipe Making Machine

Hdpe Drainage Sheet

More>>