|

QINGDAO JBD MACHINERY CO., LTD

|

HDPE heat insulation pipe extrusion line

| Price: | 80000.0~100000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Application:Heat insulation

2.Line speed:1.2m/min

3.Pipe material:HDPE

4.Screw diameter:120mm

HDPE heat insulating pipe production line of its unique structure, high degree of automation, convenient operation, continuous production of stable and reliable. The production line of the pipe with an appropriate degree of rigidity, strength, but also has good flexibility, creep resistance and environmental stress cracking resistance and good hot weld performance, has become a city heating pipes and outdoor pipes give the first choice for large-caliber Products HDPE two-storey, three double-resistant pipe extrusion production line performance and advantages: Our Company's latest two-story or three-tier spiral pipe molds for double anti-extrusion, coextrusion layer thickness uniformity, the use of inner and outer double-antibody material (flame retardant, anti-static), the ordinary core HDPE, double-antibody significantly reduced material usage, thereby reducing the cost of dual-resistant tube

Pipe sizes:

Key words: HDPE insulation pipe production line, HDPE insulation pipe extrusion line, HDPE insulation pipe machine ,HDPE insulation pipe making machinery, HDPE insulation pipe extruder,pipe extrusion line,pipe production line,plastic pipe extrusion line,plastic pipe production line, etc.

Photos of each part

1.PE heat insulation pipe extruder

2.PE heat insulation pipe mold

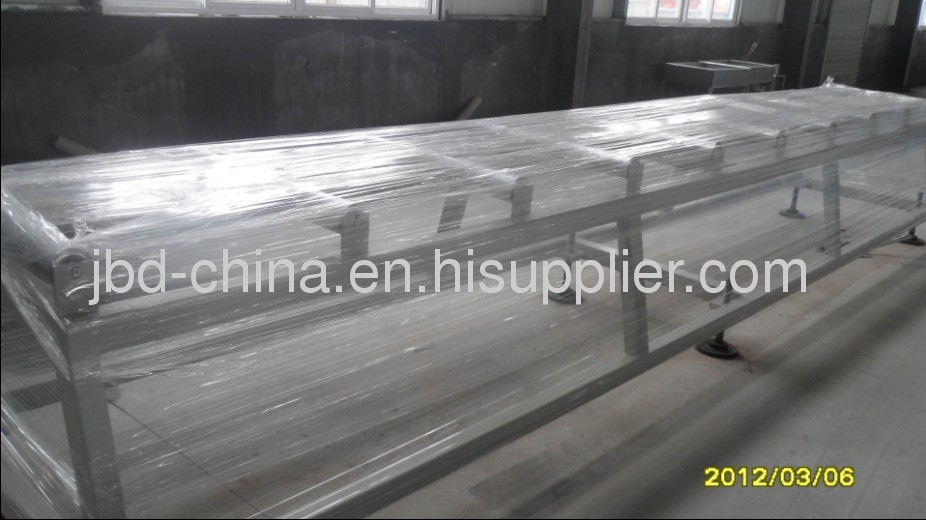

3.PE heat insulation pipe vacuum tank

4.PE heat insulation pipe spraying tank

5.PE heat insulation pipe haul off machine

6.PE heat insulation pipe cutter

7.PE heat insulation pipe stacker

Pipe sizes:

steel pipe size (mm) | wall thickness (mm) | insulating layer |

45 | 2.0 | 29 |

57 | 2.0 | 29 |

76 | 2.2 | 30 |

89 | 2.2 | 30 |

108 | 2.4 | 30 |

133 | 2.4 | 30 |

159 | 2.5 | 40 |

219 | 2.5 | 40 |

273 | 3.0 | 40 |

325 | 3.0 | 40 |

377 | 3.5 | 40 |

426 | 4 | 50 |

Photos of each part

1.PE heat insulation pipe extruder

2.PE heat insulation pipe mold

3.PE heat insulation pipe vacuum tank

4.PE heat insulation pipe spraying tank

5.PE heat insulation pipe haul off machine

6.PE heat insulation pipe cutter

7.PE heat insulation pipe stacker

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Hdpe Pipe Extrusion Line

Hdpe Pipe Extrusion

Hdpe Pipe Production Line

Pe Pipe Extrusion Line

PVC Pipe Extrusion Line

Plastic Pipe Extrusion Line

More>>